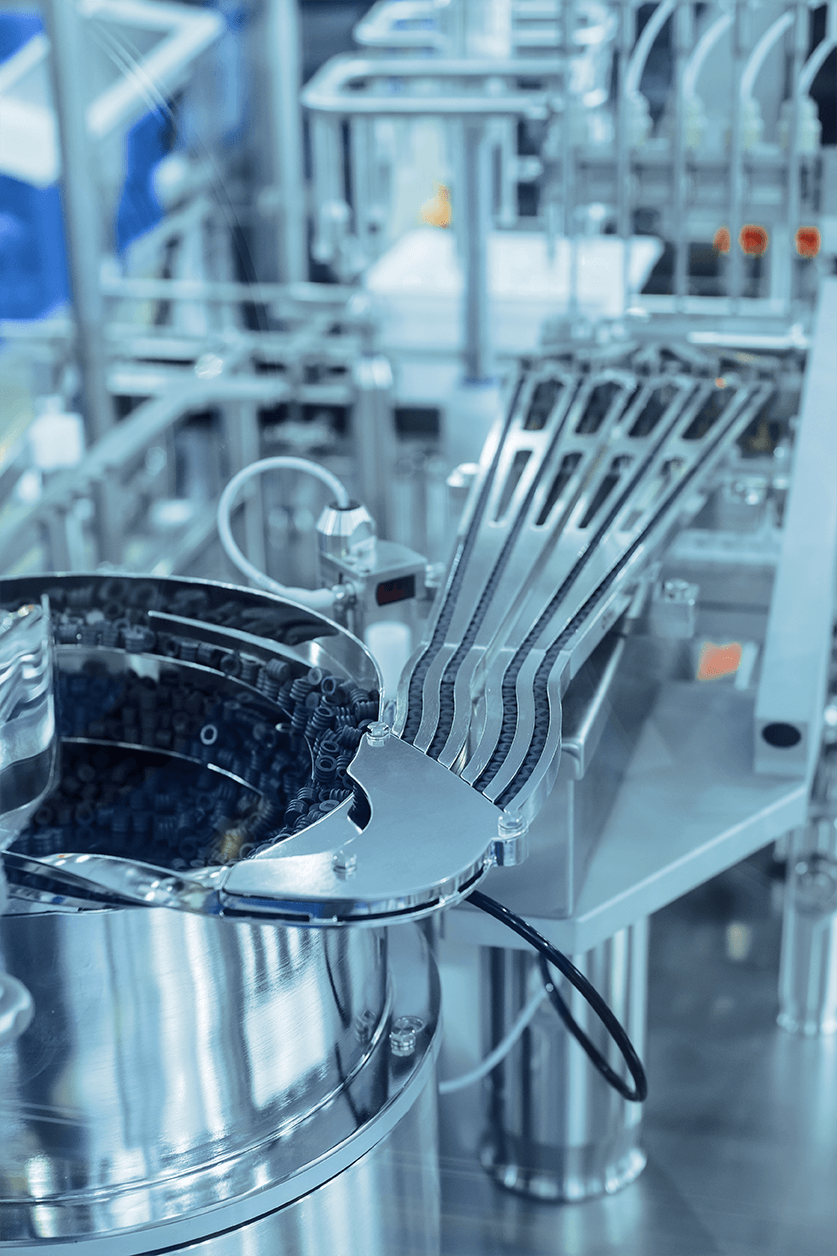

New Manufacturing Equipment Setup

Accelerate your aseptic equipment setup

Setting up new aseptic manufacturing equipment requires workflows that leave no uncertainties for staff and cover every step from process modeling and risk evaluation to compliance documentation and training. We help teams accelerate this setup through data-driven quality risk management and deep industry expertise.

Trusted by the industry

Setting up new manufacturing processes often means dealing with time pressure, missing data, and inconsistent documentation. Key documents like FMEAs or SOPs are typically created manually and rely heavily on subjective SME input. As a result, processes vary in quality and take months, sometimes years, to finalize.

Typical challenges include:

Long setup times due to unstructured or subjective input

Missing or inconsistent documentation

Lack of objective data to support process design decisions

Rework due to incomplete or incorrect process setup

Difficulty training staff on unstable or evolving processes

Process Setup with Frame-by-Frame® — Step by Step

We accelerate new equipment manufacturing set up with a structured approach that links process design, risk management, and training. The result: shorter timelines, reliable documentation, and teams that are prepared from day one. How it works:

1. Process Design and Risk Assessment

At the core of our solution is a modular process modeling and risk assessment system, powered by Frame-by-Frame® and our central process knowledge database.

Using Process Frames, we define critical interactions between people, materials, and equipment to make complex processes observable, structured, and scalable. The result: right-first-time execution with less time, complexity, and resource effort during setup.

Frame-by-Frame® enables:

2. Compliance-Ready Documentation

We generate audit-ready documentation directly from structured process data for enhanced accuracy, consistency, and mandatory alignment with regulatory expectations. All the listed materials are interlinked, ensuring traceability across design, risk, and training.

Deliverables include:

3. Comprehensive Training Package

Once the process is defined and documented, we provide targeted, role-specific training for operational readiness. Together, the program qualifies staff to operate new equipment safely, confidently, and in full alignment with the validated process.

What You Can Expect

With Frame-by-Frame®, customers reduce setup time, improve documentation quality, and create a solid foundation for qualification and training.

Process Design

>50%

faster setup

Risk Assessment

>70%

reduction in effort

Documentation & Training

>80%

faster delivery

Interested in automating quality risk management? Contact us to learn how we can assist you.

Latest topics directly to your inbox. Join our newsletter for trends and tips in aseptic training.

FAQ’s

Unlike tech transfer, new equipment setup lacks historical process validation data and established risk profiles. You’re not just replicating, you’re inventing operational reality from scratch. Risks range from equipment-user mismatches to unforeseen contamination routes. Innerspace mitigates this uncertainty by embedding risk logic and expected behaviors into the equipment onboarding process from day one.

We don’t treat equipment qualification as a checklist exercise. We systematize the why behind each test, linking qualification steps to critical quality attributes (CQAs), operator behaviors, and cleanroom interaction logic. This creates traceable, intention-driven validation that stands up in audits and reduces the likelihood of post-startup surprises.

Frame-by-Frame® acts as a logic-first scaffolding for execution: even without prior process history, we use risk-based design principles to build the process structure and training sequences. Frames are iteratively refined as data becomes available, enabling a robust foundation without delaying readiness.

We decouple training from physical availability. Operators train using simulated Frame-by-Frame® models that walk them through expected sequences, decisions, and GMP-relevant touchpoints. This creates cognitive readiness long before they step into the suite, drastically reducing the ramp-up curve.

Misalignment between user behavior and equipment intent. Most deviations post-startup stem from incorrect assumptions or mismatched mental models. We preempt this by co-modeling human-machine interactions into each process frame, aligning expectations between design, automation, and operations.

We front-load experiential knowledge through digital twins. Every piece of new equipment is embedded in a usage scenario, complete with risk logic, decision branching, and behavioral checkpoints. This gives teams a “dry run” capability that builds collective process intelligence faster than legacy onboarding can.

Risk isn’t just a post-hoc assessment – it’s a design input. We use Quality Risk Management (QRM) to identify high-exposure zones during equipment integration (e.g., manual interventions, aseptic breaches, dead leg potential) and implement targeted controls directly into SOPs, training, and operator routines.

Every equipment setup generates new insights, but they’re often lost in undocumented troubleshooting. Innerspace captures this logic through modular process frames that evolve as commissioning progresses. These updates are instantly reflected in future trainings and SOPs, ensuring institutional memory is built, not buried.

By removing the dependency on senior SMEs being physically present. Our models let teams across geographies access the same structured process logic and behavioral expectations. This creates scale without dilution, startups become repeatable, and quality doesn’t depend on who’s on-site.

Our Solutions

Better Knowledge.

Smarter Decisions.

Quality Risk Management

Automate process design and risk assessment in aseptic manufacturing with data-driven insights from our Process Knowledge Database. Reduce risks, accelerate time-to-market, and ensure quality and compliance.

Training Programs

Equip your team with the expertise needed for excellence in aseptic manufacturing through scalable, data-driven digital training solutions. Our Frame-by-Frame® method ensures effective knowledge transfer.

Innerspace is Official Partner of the Parenteral Drug Association (PDA) for designing and delivering data-driven training solutions.

We support PDA training courses through data-driven content and immersive, hands-on experiences.

What the industry says about us

We’d love to hear from you

Fill out the form, and one of our experts will get back to you shortly. Whether you have a question or need assistance, we’re here to help.